CONVEYOR EQUIPMENT FOR ROLL CAGES: ROBUST TECHNOLOGY & SIMPLE OPERATION

CONVEYOR EQUIPMENT

FOR ROLL CAGES

Roll cages are part and parcel of the grocery market delivery cycle. We guarantee maximum automation with our robust and easy-to-use conveyor system. We have accumulated 30 years of experience in the area of grocery intralogistics.

TGW conveyor equipment and sorter products are compatible with all systems, allowing smooth and high-performance processes in your intra-logistics system. Thus, the roll cage conveyors are just one part of the entire conveyor system. Learn more about our wide range of solutions and the individual products: KingDrive®, Natrix Shoe Sorter or Palett Handling.

GOOD

TO

KNOW

APPLICATION IN DIFFERENT AMBIENT TEMPERATURES TGW roll cage conveyors work flawlessly in freezers with temperatures as low as -30° C and in warehouses with temperatures up to +40° C.

30 YEARS OF EXPERIENCE We have been developing, designing and producing roll cage conveyors for over 30 years. We ensure smooth intra-logistics operations and efficiency through high precision and quality.

USER-FRIENDLY System operation is intentionally kept simple and does not require any special skills.

CUSTOMER-SPECIFIC CONVEYOR EQUIPMENT The conveyor equipment is adapted to the different sizes of the customers' roll cages

MIXED TRANSPORT OF ROLL CAGES AND PALLETS TGW's conveyor equipment is capable of transporting a combination of roll cages and pallets with a combined weight of up to 1000 kg

DURABILITY OF CONVEYOR EQUIPMENT Our roll cage conveyors are robust, low maintenance and characterised by their extraordinary durability of up to 20 years.

DIFFERENT ROLL CAGE BASES TGW's roll cage conveyors can accommodate roll cages with plastic or metal bases.

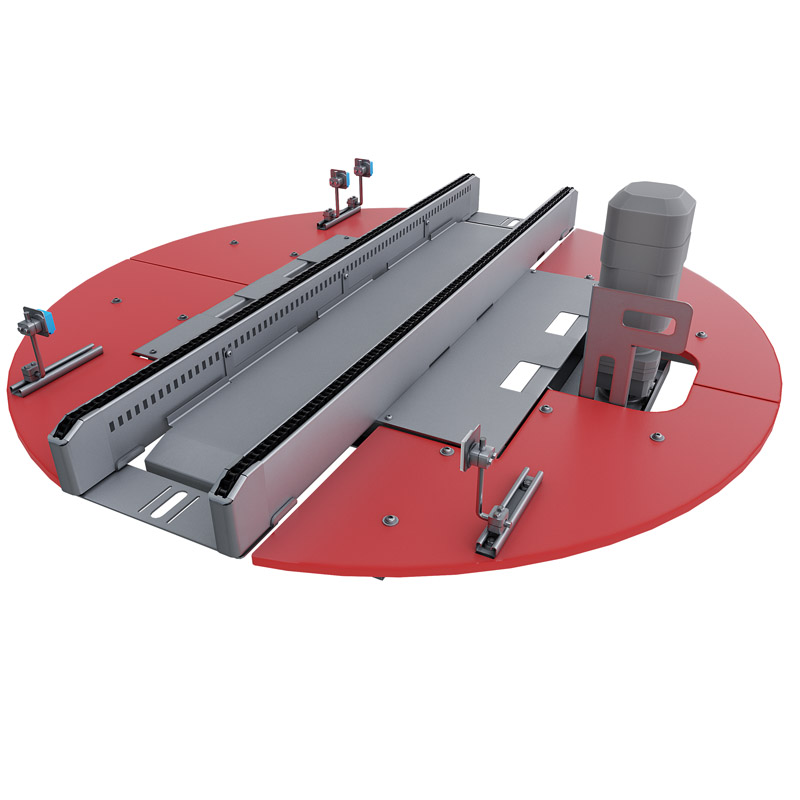

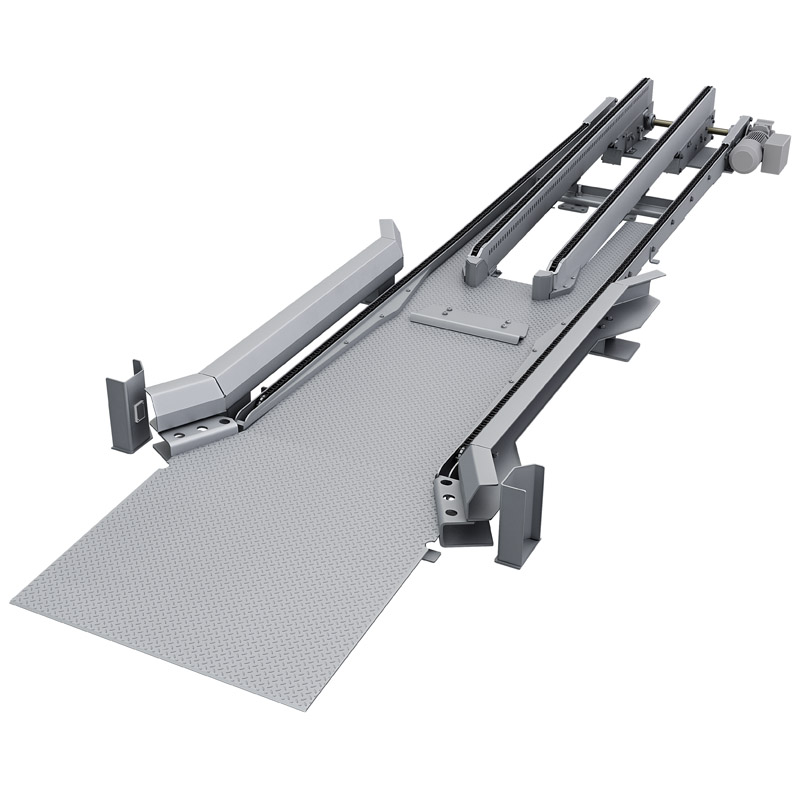

PRODUCT WORLD

The conveyor equipment for roll cages encompasses an extensive spectrum of products for fulfilling your logistical requirements in the best possible manner. Whether you need turntables, transfer cars or lifts, our modular system lets you choose from a wide range of products.

ARE YOU INTERESTED?

The following topics might also be relevant to you. If you have any questions, please contact us!